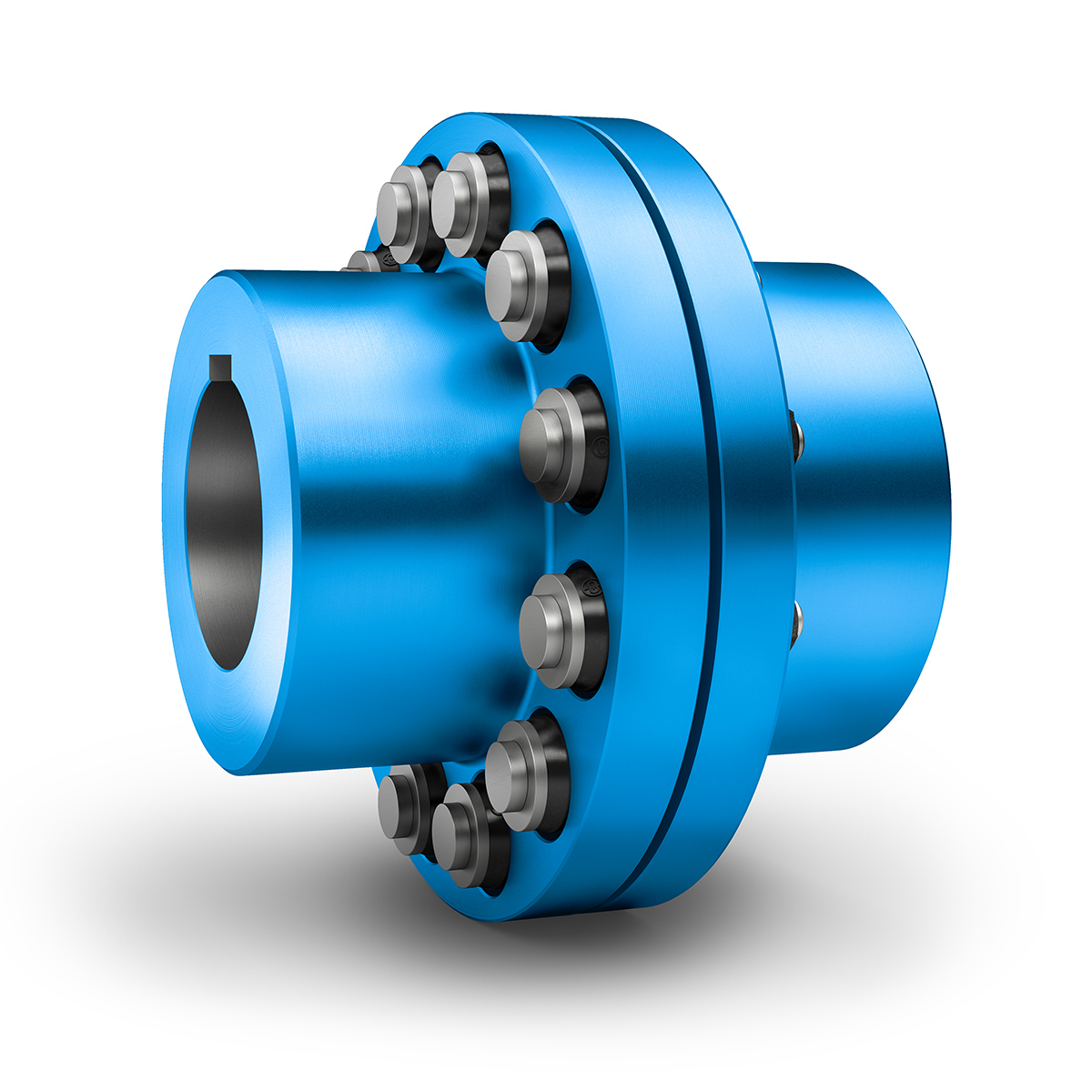

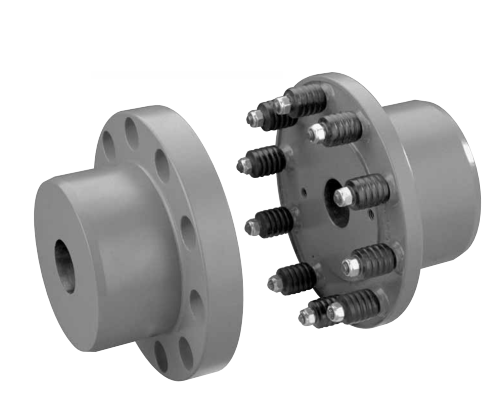

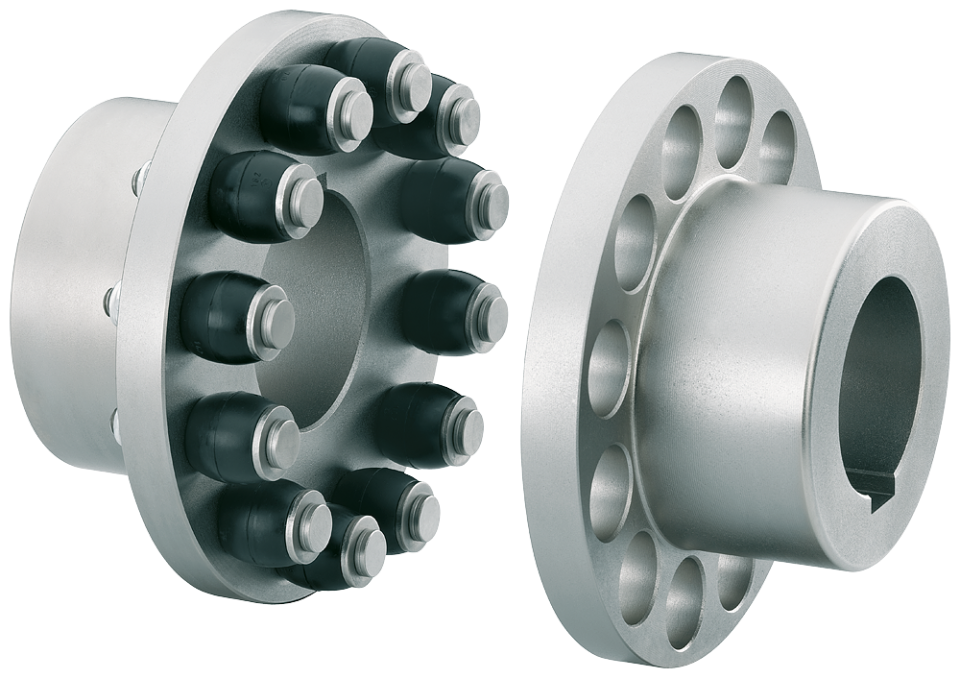

Product Description

American/Nh/ANSI Pin Type Fire Hose Coupling

Brief Description

A hose coupling is a connector on the end of a hose to connect or couple it with another hose orwith a tap or a hose appliance, such as an irrigation sprinkler. It is usually madeof steel, brass, stainless steel, aluminium or plastic. Used for combining water band with waterband ,fire hydrant ,water lance and the fire-fighting truck so that they are to supply water orfoam misture for putting out fire.

Our main production line for hose coupling is KD,KN,KY,KWA,KWS ect for fire hose coulping through electrophoretic technique,so that our product can be anti-corrosion.

Technical Specification

| Fire Hose Coupling Type | Inlet | Outlet |

| British/John Morris Coupling |

2.5″BS336 | Φ63.5 |

| 2″BS336 | Φ51 | |

| 1.5″BS336 | Φ38 | |

| 2.5″BS336 | Φ51 | |

| 2.5″BS336 | Φ38 | |

| 2″BS336 | Φ38 |

| Fire Hose Coupling Type | Inlet | Outlet |

| American(ANSI Pin)Fire Hose Coupling |

2.5″NH | Φ63.5 |

| 2″NH | Φ51 | |

| 1.5″NH | Φ38 |

| Fire Hose Coupling Type | Inlet | Outlet |

| Nakajima(Machino) fire hose coupling |

2.5″ | Φ63.5 |

| 2″ | Φ51 | |

| 1.5″ | Φ38 |

| Fire Hose Coupling Type | Inlet | Outlet |

| Forestry Fire Hose Coupling |

1.5″ | Φ38 |

| 1.5″ | 1.5″ BSP | |

| 1.5″ | 1.5″ NPSH | |

| 1.5″ | F1.5″ BSP |

| Fire Hose Coupling Type | Inlet | Outlet |

| Gost(Russian) Fire Hose Coupling |

2″ | Φ50 |

| 2.5″ | Φ70 | |

| 3″ | Φ80 | |

| 4″ | Φ100 |

| Fire Hose Coupling Type | Inlet | Outlet |

| UNI Fire Hose Coupling | UNI70 | Φ70 |

| UNI45 | Φ45 |

| Fire Hose Coupling Type | Inlet | Outlet |

| Storz Fire Hose Coupling |

4″ STORZ | Φ100 |

| 3″ STORZ | Φ75.5 | |

| 2.5″ STORZ | Φ63.5 | |

| 2″ STORZ | Φ51 | |

| 1 3/4″ STORZ | Φ44.5 | |

| 1″ STORZ | Φ38 |

Photoes

Package&Shipping

Our Company

We could supply fire hose, fire hose fittings, spray nozzle, coupling, automatic fire sprinkler system products, gate valves, check valves, ball valves, etc. All these products strictly confirming to JIS, API ans BS standards. All of our products comply with international quality standards and are greatly appreciate in avariety of markets around world. Our factory is covering an area of 15900 square meters, we now over 300 workers. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarteen total customer satisfaction. As a result of our high quality products and outstanding customer service, we have gained a globe sales network CHINAMFG the North America, South America, Mideast, Southeast Asia, East Europe, etc.

Certificate

Other Fire Fighting Equipment

FAQ

1. Could you supply the samples?

Free samples always ready if the value is within our purview.

2.Do you have the MOQ?

For conventional products, Low MOQ.

3. Can you add some logo on the products?

Yes. We could OEM and design your logo.

4. Are you able to design or explore a new products for us?

Yes, we are able to, if the clients could supply the drawings or samples.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GB8013-2005, CCCF, CCC |

|---|---|

| Surface Treatment: | Chrome Plated/Brass |

| Material: | Aluminum/Brass |

| Type: | British/John Morris/ American/Nh/Nakajima(Machino) |

| Application: | Fire Hose Coupling |

| Transport Package: | Bags/Cartons |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are There Any Safety Considerations When Using Pin Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using pin couplings in rotating machinery. These considerations are essential to ensure the safe and efficient operation of the equipment and to protect personnel working in the vicinity. Here are some key safety points to consider:

- Guarding: When installing pin couplings, it is crucial to provide adequate guarding around the coupling area. This helps prevent accidental contact with the rotating coupling components, such as pins and hubs, which could cause severe injuries.

- Maintenance and Inspection: Regular maintenance and inspection of the pin coupling are vital to identify any signs of wear, misalignment, or damage. Any worn or damaged components should be replaced immediately to prevent coupling failure, which could lead to sudden equipment shutdown or safety hazards.

- Proper Alignment: Ensuring precise alignment of the connected shafts is crucial to the safe operation of the pin coupling. Misalignment can lead to increased stresses and premature wear on the coupling components, resulting in potential failures.

- Torque and Speed Limits: Adhering to the manufacturer’s recommended torque and speed limits for the pin coupling is essential for its safe operation. Exceeding these limits can lead to overloading and failure of the coupling.

- Environmental Considerations: Take into account the operating environment when selecting a pin coupling. Extreme temperatures, corrosive atmospheres, or harsh conditions may require special materials or coatings to ensure the coupling’s integrity and prevent premature failure.

- Training and Awareness: Operators and maintenance personnel should receive proper training on the safe handling, installation, and maintenance of pin couplings. Awareness of potential hazards and safety protocols is crucial for the safe use of rotating machinery.

- Emergency Shutdown: Install emergency shutdown systems that can quickly stop the rotating machinery in case of any safety concerns or abnormal conditions.

- Compliance with Regulations: Ensure that the use of pin couplings complies with all relevant safety and industry regulations and standards.

By taking these safety considerations into account and implementing proper safety measures, the use of pin couplings in rotating machinery can be done safely and effectively, mitigating potential risks and ensuring a safe working environment for personnel.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Limitations and Disadvantages of Using Pin Couplings

While pin couplings offer various advantages and are suitable for many applications, they also have some limitations and disadvantages to consider:

- Misalignment Restrictions: Pin couplings can accommodate a certain degree of misalignment, but excessive misalignment can lead to increased wear and stress on the coupling components. They are not as effective at handling large angular or parallel misalignments compared to other flexible couplings like gear or elastomeric couplings.

- Less Damping Capacity: Pin couplings have limited damping capacity, which means they may not effectively absorb and reduce vibrations in the system. In applications where vibration damping is critical, elastomeric or flexible couplings may be more suitable.

- Noisy Operation: The rigid nature of pin couplings can lead to increased noise during operation, especially at high speeds or in applications with significant misalignment. This noise can be a concern in environments where noise levels need to be minimized.

- Higher Maintenance: Compared to maintenance-free couplings like certain types of elastomeric couplings, pin couplings may require more frequent inspection and maintenance. The pins and other components may experience wear over time and need replacement.

- Environmental Limitations: Some pin couplings may not be suitable for use in corrosive or high-temperature environments, depending on the materials used. Stainless steel or other corrosion-resistant materials can help mitigate this limitation.

- Size and Weight: In certain applications, the size and weight of pin couplings may be larger and heavier compared to other types of couplings. This can be a consideration in applications where weight is a concern or space is limited.

Despite these limitations, pin couplings remain a popular choice for many applications where their advantages, such as simplicity, durability, and cost-effectiveness, outweigh their disadvantages. It is crucial to carefully assess the specific requirements of the application and consider factors like misalignment, vibration, maintenance needs, and environmental conditions when selecting a coupling type.

editor by CX 2024-04-25

by

Tags:

Leave a Reply