Product Description

| Part Name | Ball Size | Capacity | Finish | |||

| Trailer Gooseneck Ball | 50mm | 3500KG | Black,Chrome,Zinc Plated | |||

- 3500kg (3.5T) on the road

- 50mm Ball

- 20mm diameter pin

- Standard mounting holes (90mm centres)

- Needs at least M16 bolts (at least 8.8 grade)

Our 50mm Gooseneck Hitch Ball is the perfect solution for towing up to 3500kg (3.5T) on the road. With a 50mm ball and 20mm diameter pin, it’s compatible with a wide range of trailers. The hitch ball features standard mounting holes with 90mm centres, making it easy to install on your trailer. For added safety and security, it requires at least M16 bolts with a minimum grade of 8.8. Whether you’re hauling equipment or transporting goods, our hitch ball is a reliable and durable choice for all your towing needs.

HangZhou CHINAMFG Machinery Co., Ltd is a professional manufacturer of trailer parts in HangZhou, ZHangZhoug Province, China since 2016.

We can produce many trailer parts & accessories as follows: Towbars, axles, brake drums, hubs, brake disc, bearings, springs and springs and suspension kits, couplings, mudguards, U-Bolts, Jockey Wheels, keel rollers and brackets, wobble roller, wheel spacer, equalizers and all accessories related to trailers.

If you can send me the drawings or specifications of the trailer parts, mechanical parts and wheels, we can give you our price.

Q1: Do you have factory?

A: Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

Q2: Can I have a sample order?

A: Yes, welcome sample order to test and check quality. Mixed samples are acceptable.

Q3: It’s OK to print my logo on your product?

A: Yes, we can according to your exact requirement.

Q4:How do you ship the goods and how long does it take arrive?

A: We usually shipped by DHL, UPS, FedEx, it usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5: What is your advantages?

A: We are professional supplier for more than 10 years, we always put the quality and price at the first place. At the same time, our products are exported to various countries, we have full experience to solve thorny problems.

If you want to know about our products and us, welcome to enquiry and email me.thanks

1-Welcome OEM

- You can use your own brands or ours, if you use our brand, our professional team will help you design the packing.

2-Our service

- You inquiry related to our products or prices will be replied in 24 hours.

- Well-trained and experienced staffs to answer all your enquirys in fluent English.

- Protection of your sales area, ideas of your design and all your private information.

- We have a QC team, every product will be checked by them before packed.

3-Welcome to visit

- When you come to our company visit us, we will arrange a car for picking up and help you book hotel. If you want to visit the local scenic spot, our colleague will accompany you.

4-Warranty

- Customer should be provide the video and the pictures for the problem products.

- Products returned within the warranty period must bear product number & date code.

5-After service

- In production and after delivery, we will track on time and tell you goods situation.

- When the goods arrived, if you find any design and quality questions, or difference from your samples, please feel free to contact us, we will find the question and solve it with you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Towing Pin |

|---|---|

| Certification: | ISO |

| Loading Weight: | 2T |

| ABS: | Without ABS |

| Tent Type: | Simple |

| Axle Number: | 2 |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

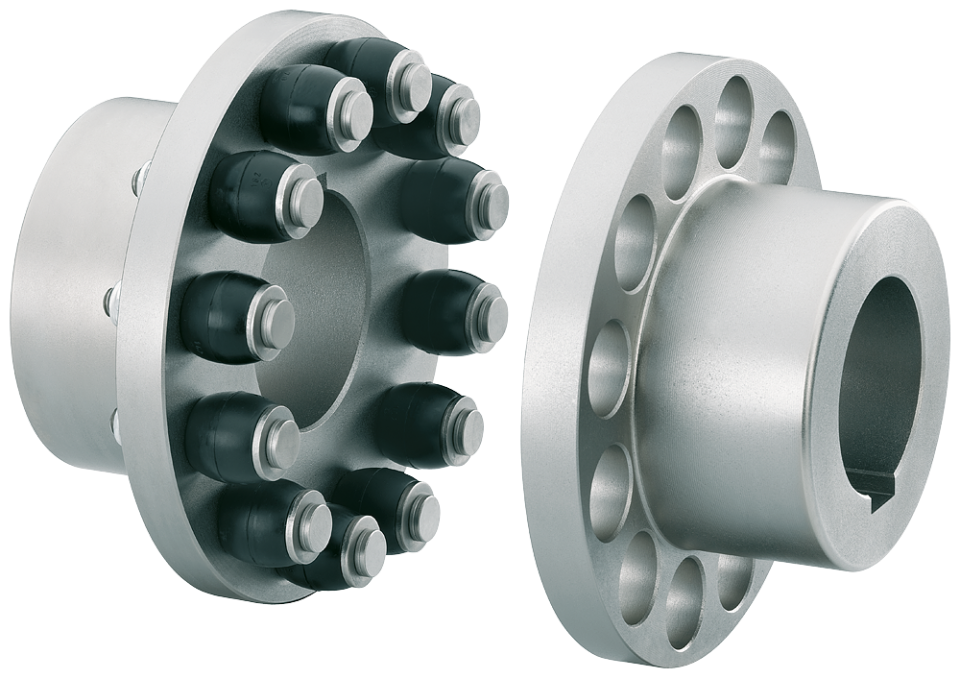

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

Types of Pin Coupling Designs

Pin couplings, also known as shear pin couplings, come in various designs to suit different application requirements. The main types of pin coupling designs are as follows:

- 1. Single Pin Coupling: In this design, a single shear pin is used to connect the two shafts. The pin is placed in a hole that runs through both coupling halves. Under excessive torque or shock loads, the pin shears off, disconnecting the shafts and protecting the equipment from damage. Single pin couplings are commonly used in light to moderate-duty applications.

- 2. Double Pin Coupling: Double pin couplings use two shear pins that are positioned 180 degrees apart. This design provides increased torque capacity and improved balance compared to the single pin design. Double pin couplings are suitable for applications with higher torque requirements.

- 3. Triangular Pin Coupling: Triangular pin couplings use three pins arranged in a triangular pattern around the circumference of the coupling. This design offers even higher torque capacity and improved torsional stiffness. Triangular pin couplings are ideal for heavy-duty applications where higher torque and misalignment tolerance are essential.

- 4. Splined Pin Coupling: Splined pin couplings use splines instead of solid pins to transmit torque between the shafts. The splines provide a more secure connection and better torque transmission compared to solid pins. Splined pin couplings are commonly used in precision motion control applications.

- 5. Taper Pin Coupling: Taper pin couplings use tapered pins that wedge tightly into matching tapered holes in the coupling halves. This design offers excellent torque transmission and alignment capabilities. Taper pin couplings are often used in heavy machinery and power transmission systems.

Each type of pin coupling design has its advantages and limitations, and the selection depends on factors such as the application’s torque requirements, misalignment tolerance, and environmental conditions. It is essential to choose the right type of pin coupling to ensure optimal performance, reliability, and safety in the mechanical system.

editor by CX 2024-04-25

by

Tags:

Leave a Reply